The touch screen has become one of the promoters of this new connected society in which we all use our smartphone, tablet or any other similar device daily. And it is that, without them, it would be really complicated that the so complex operating systems of our mobiles had been developed. However, as with almost any object that becomes daily in our life, we lose the sense of its operation. It becomes so obvious that we don’t even ask ourselves what is the technology behind it. A Capacitive Touch Screens is a type of capacitive sensor that is made up of an electrical insulation layer and that is covered with a transparent conductor. Since the human body is an electrical conductor, when contact is made with the surface of said screen, a distortion of its electromagnetic field is generated. This field is measured thanks to the change in capacitance, also called electrical capacity. Different technologies can be used for this. The position must be sent to the controller for processing. In addition, these types of screens allow to obtain a higher quality image, with an improved response and, in some cases, the use of several fingers at the same time is allowed. However, these are more expensive displays and should not be used with a common type pointer, but will require a specific pointer for a capacitive display. A touch screen is something like an invisible keyboard attached to the front of a monitor. To understand how Capacitive Touch Screens work, it is first vital to know how an ordinary keyboard works, where basically each key is an electrical switch. When one of them is pressed, a circuit is completed and a current flows, which varies depending on the key that is pressed and this is how the team realizes what we are writing Touchscreens try to achieve something similar to normal keyboards but obviously cannot use switches, plastic membranes and other materials, since otherwise they would obstruct the visibility of what is shown on the screen, so they must use clever tricks to detect touch completely invisible.

How does the touch screen work?

The capacitive touch panel sensor screen is a four-layer composite glass screen, the inner surface glass screen and the sandwich coated with a conductive layer layer, the outermost layer is a thin layer of the protective layer made of siliceous glass. When we touch the screen with the finger on the sensor screen, the electric field of the body and the touch screen and the surface of the touch screen to form a coupling capacitor, for high-frequency current, the capacitor is a direct conductor, so the fingers from the aspiration contact point a small current. This current flows out of the electrodes at the four corners of the touch screen, and the current flowing through the four electrodes is proportional to the distance from the finger to the four corners. The controller calculates the position of the contact point by accurately calculating the four current ratios. It was only a few years ago when the only touchscreen devices I could find in consumer devices were those on tablets, smartphones, and stylus PDAs. At the time, touchscreens were too expensive to replace the exact and precise mouse or keyboard. Touchscreen technologies have been incorporated into a wide range of devices such as mobile phones, ATMs, GPS, televisions, and other modern devices. These types of screens are those that currently surround us. In fact, they are the screens of most current mobile phones. The operation is based on the fact that a fixed mass, which is the screen itself, is charged with electricity. This load is flat and static. However, when we press the screen, this electric charge changes, causing it to stop being flat and, in this way, thehis technology, so using your fingers to close an electrical circuit will make it extremely simple to accurately detect human contact area where pressure has been applied is detected

What is HMI human-machine interface?

HMI is where people and machines connect. This interaction makes it easier for the human operator to enter control of a machine and monitor machine feedback information. The HMI can be found in devices from dial adjustment on a mechanical watch to portable devices that detect touch. Another example of a human-machine interface is the steering wheel of a car or the computer touch screen for driverless cars. These HMI interfaces are currently displays with an added touch sensor on the front. This provides immediate and intuitive feedback to the user. Originally designed from short-lived commercial products, touchscreens are in demand as supplies for industrial machinery

What is a Display?

Basically, the displays are layers of glass with liquid between them, a light source, and thin transistors that control the liquid to selectively block light, creating an image. These layers are called the “stack” screen and can be 10 or more depending on the solution required. If you need to modify a standard display to be rugged, improve optical performance, increase brightness, add a touchpad, or add a custom metal frame, then integration services are required to create a custom blend. Screens are cut from large sheets of glass, and only a few manufacturers make the sheets of raw glass. Glass is etched and transistors etc. are printed on the glass. Protection glass The glass is cut into sizes that obtain the maximum number of outlets, mall displays, transportation information and sample with the least amount of glass wasted

What is a Touch Panel

You probably wear one of these every day, and yet it’s invisible to you. The touchpad has become the human-machine interface for most devices. We previously had the electronic keyboard, mouse, stylus, or micro-thumb sensor to enter data into a machine, phone, or laptop. One of the biggest advantages of a touchpad is its openness. The touchpad is so intuitive that even children understand how to get the results they want. When people see a screen, they are now expected to touch and swipe it and then get confused if the screen image doesn’t change.

How Capacitive Touch Screens Works?

Touchscreens work in different ways. Some can only detect one finger at a time and become too confused if two different places are pressed at the same time, while others can with this action. The arrival of touchscreens in our lives brought “swear words” like “resistive screen” or “capacitive screen” that in the end many people cannot distinguish. Touchscreen devices have a two-dimensional detection system that is made of 2 sheets of material and dividers to separate these sheets. Humans are good drivers of this technology, so using your fingers to close an electrical circuit will make it extremely simple to accurately detect human contact. Touchscreens have 3 vital components: a touch sensor, a touch controller, and a software controller. The screen itself is an input device, and the touch input system can be completed by combining it with a monitor or PC.

Touch sensor

A touch sensor is a transparent glass panel on which the touch surface is highly sensitive. Each sensor would use a different method to detect the input. This touch panel is placed on top of a display screen so that the display area of the video screen is covered by the sensitive area of the panel. There are numerous touch sensor technologies on the market, each of which uses different methods to detect touch input. This sensor will also have an electrical signal going through it and touches the screen to cause a signal or voltage change. This signal change is used to discover the location of the touch on the screen.

Touch controller

The touch controller is a PC card that is connected between the PC and the touch sensor. It is usually installed inside the touch monitor to integrate monitors. The controller translates the information from the touch sensor into information that the PC can understand. The driver will determine the type of connection the PC needs. There are built-in touch monitors that have a cable connection on the back of the screen. Other specialized drivers in Capacitive Touch Screens are available and will work on DVD players and other devices.

Software driver

This driver will provide a software update for the PC system that would allow the touch screen and PC to work together. This determines how the PC operating system would interpret the touch event information sent from the controller. Most touch screen drivers emulate the mouse type driver. In this way, touching the screen would be the same as clicking the mouse on the same location on the screen. This enables the touch screen to work with existing software and provides the opportunity to create new applications without the need for specific touch screen programming. Devices such as specialized computer systems, thin client terminals, and DVD players do not use software drivers or have their own built-in touch screen driver. The touchscreen is one of the simplest PC interfaces to use, making it the ideal interface for a variety of applications. Touchscreen devices have gained prominence over the years with a constant drop in price in the last decade. Touchscreens are commonly used in ATMs, PDAs, cell phones, supermarket terminals, and more prominently in video games.

Advantages of capacitive Touch Screens

A capacitive screen works by capacitance. This implies that it brings a much faster and more intuitive experience when the user uses it. These screens do not require any pressure or force to carry out the action. Rather, simply place your finger lightly on the screen. Another advantage of Capacitive Touch Screens is that it is a system that offers the ability to support multiple screen touches at the same time, what is known as multi-touch. In this way, the interaction speed can be further expanded by allowing different orders to be executed at the same time.

- Ease of use.

- It is the most intuitive system to handle any electronic element.

- The wide range of sectors in which such technology can be applied.

- The decrease in the use of input peripherals in the computer such as keyboards, mouses, etc.

Disadvantages of capacitive Touch Screens

- Depending on the size of the screen, the appearance of the fingers of the person using it may be a problem.

- They are very delicate in the sun and dirt.

- Fat accumulated on the tips of the fingers can affect them.

- Extreme fragility in the face of blows, scratches, etc.

Contact points of a capacitive touch screen

When you want to use a screen with the ability to detect multiple points of contact, for example when zooming with two fingers, in addition to the screen itself, you will need special software. This software must be adequate and powerful enough to understand what is happening on the screen regarding the electric field so as not to confuse the points that are being pressed.

From capacitive screens to resistive screens

During 1970, the technology was not mature, but that did not prevent engineers like Stumpe, Beck, Johnson or Dr. Sam Hurst (University of Kentucky) to design and patent new ways of making screens tactile. The first designs were based on capacitive technology supported by electrical impulses. This means that the screen was able to detect where we had placed our finger (at that time only one) thanks to the fact that the human body acts as an earth connection for an exceptionally weak current: When personal computers were a thing of the future and smartphones didn’t even smell, a 1982 BBC report left the English open-mouthed with a touchscreen computer.

Broadly speaking, we could say that touch screens can be:

- Resistive: They are cheaper and are not affected by dust or water, and in addition to being more precise, they can be used with a pointer or finger. However, they lose up to 25% of the brightness and are thicker, so they are being replaced by others on mobile devices that require a adjusted size and weight and higher brightness on the screen due to the possibility of being exposed to light. direct from the sun.

- Capacitive: The image quality is better, they have a better response and some allow the use of several fingers at the same time (multitouch). However, they are more expensive and cannot be used with a normal pointer, but with a special one for Capacitive Touch Screens

- Infrared: Infrared technology bases its operation on the use of infrared emitters and receivers installed along the X and Y axes. This generates an infrared light matrix on the entire surface of the touch screen, so that when a point is touched, the infrared beam is interrupted on both axes, the controller detecting the coordinate where the touch occurs. Among the advantages is that it can be touched in addition to the finger, with any other object or with gloves. They are also multitouch although they are more expensive. The latest are infrared LED displays.

The following infographic explains the difference between resistive, Capacitive Touch Screens and infrared screens in a more or less summarized way.

What is the difference between resistive, Capacitive Touch Screens and infrared screens?

We are going to try to explain the difference between having a device with a Capacitive Touch Screens or resistive screen. And the screens are not all the same? Well, it will be no. With the arrival of devices governed by OSX or Android, the type of screens used so far for touch devices had to be changed. Before the Iphone in most of the tactile devices, Windows Mobile was installed and it was necessary a stylus or stylus or whatever you want to call it, to be able to use the phone. Apart from the fact that the system itself was not prepared to be used with the fingers since the menus were small, the on-screen arrangement of the options prevented the use of the finger for its execution and there are many functions that, apart from the pen tip cannot be run.

Resistive Screens

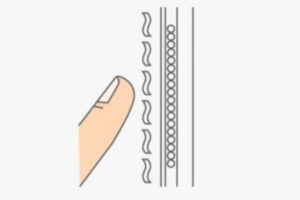

Basically, a resistive touch screen is made up of two very thin and transparent conductive plastic film layers, located on the screen itself, which allows you to measure the change in resistance produced when the electrical connection is made due to the union of these layers when pressed with your finger or stylus. Resistive touch screens are much cheaper to manufacture than the rest, but they do not offer the possibility of multitouch, that is, if we pressresistive touchscreen with more than one finger, the device will capture the position of only one of them. In addition, these are decalibrated over time and must be recalibrated. A resistive touch screen is made up of several layers. The most important are two thin layers of conductive material between which there is a small gap. When some object touches the surface of the outer layer, the two conductive layers come into contact at a specific point. This produces a change in electrical current that allows a controller to calculate the position of the point where the screen has been touched by measuring resistance. Some displays can measure, apart from the contact coordinates, the pressure that has been exerted on it. Resistive touchscreens are generally more affordable but have a loss of approximately 25% of the brightness due to the multiple layers required. Another drawback they have is that they can be damaged by sharp objects. On the contrary, they are not affected by external elements such as dust or water, which is why they are the most widely used type of touch screen today. The five most commonly used touchscreens are: 5-wire resistive, projected capacitive, surface capacitive, infrared, and surface acoustic wave (SAW).

5-wire resistant

5-wire touch resistor is the most widely used touch technology. A resistive touch screen is made up of conductive layers; a normal optical glass surface covered with two metallic layers, one resistive and the other conductive, and finally a scratch-resistant protective screen that covers everything. When the user touches the LCD screen, the pressure creates a contact between the conductive and resistive metal layers. Then a change in the electronic field is monitored. This transition is then recorded by the electronic circuits used within the device, and the data is passed to the firmware, which in turn processes and then forwards the data to the devices’ operating system. The operating system will produce an on-screen display of the captured motion or action (mouse click or drag, etc.).

Advantages of Resistive touch screens:

*It can be activated with practically any object: finger, pencil, gloved hand, pen, etc. *It has tactile sensation *Lower cost touch technology *Low energy consumption *Resistant to dust, oil, grease, humidity and other liquids.

Disadvantages of Resistive touch screens

*Lower image definition compared to other touch technologies *The outer polyester film is vulnerable to damage by scratches, punctures and sharp objects. *Diffuses light output from LCD backlights

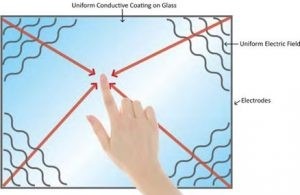

Surface Capacitive

This type of touch technology works in a remarkably different way than a resistive touch screen. A layer that stores an electrical charge is placed on top of the glass in the front window of the LCD screen.

Surface capacitive touchscreen

Once this special layer is touched, a very small electrical charge is transmitted to the finger that came in contact with the screen, effectively reducing the amount of charge in the layer. This change in electrical charge is controlled by touch sensors located in the corners of the touch window. The sensors then pass the data to the device driver software and then to the operating system, and in turn is displayed if the screen occurs. With a capacitive touchscreen, a conductive input arrangement, such as a finger or a specific input device, must be used.

Advantages of Surface capacitive touschscreens:

*Much better image clarity than resistive touchscreens *Screen more durable than the resistive type. *Excellent resistance to contaminants and surface liquids: dust, oil, grease, water drops. *High scratch resistance *Does not diffuse light output from LCD backlights

Disadvantages of Surface capacitive touchscreens

*Requires bare finger or specific capacitive pen for activation *Sensitivity to electromagnetic interference (EMI) and / or radio frequency interference (RFI)

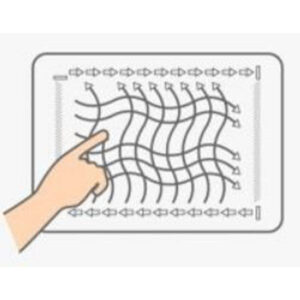

Projected Capacitive

The projected capacitive is similar to the surface capacitive, sometimes called PCAP or PCT, it is an ideal preference for a wide range of applications, including industrial use as process control terminals, medical displays, and telemetry systems for agricultural vehicles because Touch performance is not affected by dust and dirt scratches on the touch window. Compared to surface capacitive technology, PCAP offers two main advantages: In addition to a bare finger, it can also be activated with surgical gloves or thin cotton gloves. Projected capacitive touch panelFor some PCAP windows, they can also be operated by a user wearing thick gloves and can be sealed to high ingress protection ratings, making them suitable for challenging or outdoor deployments. PCAP also allows multi-touch activation (simultaneous input of two or more fingers). A projected capacitive screen consists of a sheet of glass with embedded transparent electrode films and an integrated chip that creates a three-dimensional electrostatic field. When a finger makes contact with the screen, the proportions of the electrical currents change and the computer can detect the contact points.

Advantages of projected capacitive touch panels:

*Excellent image clarity *More scratch resistant than surface capacitive touchscreens *Resistant to surface contaminants and liquids: dust, oil, grease, moisture. *Multi-touch (two touches)

Disadvantages of projected capacitive touch panels

*Sensitive to EMI / RFI *Must be activated with exposed finger, thin surgical gloves or cotton gloves, although some PCAP windows (such as those used by AbraxSys) can be activated with a heavy gloved hand

Infrared touch screens

Infrared technology bases its operation on the use of infrared emitters and receivers installed along the Y and X axes. This generates an infrared light matrix on the entire surface of the touch screen, so that when a point is touched, the infrared beam is interrupted on both axes, the controller detecting the coordinate where the touch occurs. Unlike other technologies, infrared touchscreens do not overlap the screen with an additional layer. These types of touchscreens are based on light beam interruption technology. It uses infrared emitters and receivers to create an invisible grid of infrared light beams across the screen. Not having an additional film or layer means the best possible image quality and clarity. A sensor detects a person’s touch when an object interrupts light rays. This enables multi-touch functionality and also does not require the user to apply pressure to register a touch. Even if the screen is scratched, it works completely fine and other objects besides the fingers can be used to work, which makes the use of gloves not a problem. The only downside to this technology is that sunlight can sometimes affect its functionality. Among the advantages is that it can be touched in addition to the finger, with any other object or with gloves. They are also multitouch, although it has clear disadvantages; They are expensive and bulky, as well as very sensitive to dirt.

Advantages of Infrared Touch:

*Maximum image clarity and light transmission from all touch screen technologies. *Unlimited “tactile life” *Impervious to surface scratches.

Disadvantages of Infrared Touch

*Accidental activation can occur because infrared rays are actually on the glass surface *Dust, oil, or grease buildup on the screen or frame may prevent the light beam and cause a malfunction. *Sensitive to water, snow and rain. *It may be sensitive to interference from ambient light. *Higher cost

SAW Touch touchscreens

A surface acoustic wave (SAW) touch screen works a little differently than resistive and capacitive touch screens. They use transducers mounted on the edge of a glass panel that create an invisible network of surface ultrasonic waves that receive the sensors, hence the name surface acoustic wave. SAW surface acoustic touch screenTwo acoustic waves inaudible to humans are transmitted through the glass surface. One of the slings is transmitted horizontally and the other vertically. Each wave is scattered across the screen surface, bouncing off acoustic reflectors. The controller circuit measures the moment it receives an attenuated wave and determines the coordinates of the contact point. When a user touches the screen, part of this wave is absorbed. The receivers locate the point of contact and send this information to the computer. SAW touchscreens can be activated with a finger, a gloved hand, or even a stylus. They are easy to use and offer high visibility, as well as high optical clarity and long life. They have some disadvantages, for example, not being able to use with hard objects such as pens, credit cards or nails. False touches are also a risk, especially from water droplets, while solid contaminants on the screen can create non-touch areas until

Advantages of surface acoustic wave SAW Touch solutions:

Excellent image clarity Even better scratch resistance than capacitive touch windows Long useful life

Disadvantages of surface acoustic wave SAW Touch solutions:

It won’t activate with hard items like a mechanical pen, nails, or even a credit card. Water droplets can cause false triggering and triggering Solid contaminants on the screen can generate non-touch areas until dirt / dust is removed

Optical infrared touch screen

Due to its flexibility, optical infrared (IR) is another very popular technology. In particular, IR is the only touchscreen that works without a film or glass cover layer. Instead, it relies on infrared light-emitting diodes that project an invisible grid of beams that record contact where light is interrupted. It offers great clarity, is easy to calibrate, and also lasts a long time, as there is no flexible layer that will degrade over time. The main drawback is the presence of a noticeable gap between the flat panel and the IR sensors. For this reason, it is less suitable for high traffic and industrial applications where dust, debris, or high pressure liquids can damage the electronic components inside the LCD panel. The optics are clearer than resistive or capacitive touch, provide a rugged surface that manufacturers can beautify and seal against dust and moisture, and support multi-touch and double-touch inputs. Mainly produced in sizes over 32 inches, IR technology is ideal for use with kiosks, outdoor facilities, point of sale systems, factory automation, and other applications where bare fingers are impractical, from pharmaceutical and industrial settings to retail stores, hospitality and service industries