Optical Bonding is a specialized process that enhances the performance and durability of LCD displays, particularly in challenging environments. It involves filling the air gap between the LCD and the glass with a resilient adhesive or resin, such as silicone. Once cured, the silicone delivers a range of significant advantages, including improved sunlight readability, enhanced touchscreen accuracy, and protection against harsh conditions.

Advantages of Optical Bonding

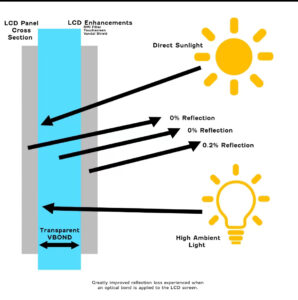

When you choose Optical Bonding for your industrial computers and monitors, you unlock a world of benefits. One of the most notable advantages is a reduction in refraction and glare. By absorbing and diffusing light, bonded displays ensure excellent sunlight readability, making them ideal for outdoor usage. Optical Bonding boosts the display’s durability, making it capable of withstanding vibrations, water exposure, and dust. This ruggedness is perfect for public access areas, factories, and other challenging environments.

The Problem with Air Gaps in Displays

In standard viewing environments, the air gap between the front glass and the LCD module of a display doesn’t present any significant issues. However, this tiny gap can be problematic for displays placed in demanding conditions, such as outdoor installations. It can result in impaired viewing performance, increased glare, and reduced readability, especially in bright sunlight. Fortunately, Optical Bonding addresses this problem by eliminating the air gap and significantly improving the display’s performance.

Why choose Optical Bonding for your displays?

Selecting Optical Bonding for your industrial computers and monitors is a smart choice for various reasons. It dramatically enhances your displays’ performance by reducing glare and making them sunlight-readable. It increases the overall durability of your displays, ensuring they can withstand harsh conditions. Optical Bonding also prevents the inconvenience of condensation and fogging in humid environments, providing consistently clear visibility. It improves touch accuracy, allowing for precise and responsive interactions. When it comes to optimizing your displays for demanding applications, Optical Bonding is the solution you’ve been searching for.

Types Of Materials

Silicone’s core properties of low conductivity and chemical reactivity, thermal stability, and ability to repel water and form watertight seals make it a common solution for optical bonding.

Epoxy

Epoxy makes a much more rigid bond than silicone, but does not tend to form particulate debris. It is not reworkable if any problems arise during production or use.

Polyurethane

Polyurethane adhesives possess good environmental integrity for use in high altitudes and may be superior at low temperatures. It does exhibit a yellowing over time when exposed to high solar lighting.

Where you can find Optical Bonding?

At Wis-view, we offer an Optical Bonding LCD solution as a feature. You can find Optical Bonding on our website,:www.wis-view.com

Hi, this is a comment.

To get started with moderating, editing, and deleting comments, please visit the Comments screen in the dashboard.

Commenter avatars come from Gravatar.